Axles

- Thread starter bombmachinist

- Start date

-

From all of us at Scout Motors, welcome to the Scout Community! We created this community to provide Scout vehicle owners, enthusiasts, and curiosity seekers with a place to engage in discussion, suggestions, stories, and connections. Supportive communities are sometimes hard to find, but we're determined to turn this into one.

From all of us at Scout Motors, welcome to the Scout Community! We created this community to provide Scout vehicle owners, enthusiasts, and curiosity seekers with a place to engage in discussion, suggestions, stories, and connections. Supportive communities are sometimes hard to find, but we're determined to turn this into one.

Additionally, Scout Motors wants to hear your feedback and speak directly to the rabid community of owners as unique as America. We'll use the Scout Community to deliver news and information on events and launch updates directly to the group. Although the start of production is anticipated in 2026, many new developments and milestones will occur in the interim. We plan to share them with you on this site and look for your feedback and suggestions.

How will the Scout Community be run? Think of it this way: this place is your favorite local hangout. We want you to enjoy the atmosphere, talk to people who share similar interests, request and receive advice, and generally have an enjoyable time. The Scout Community should be a highlight of your day. We want you to tell stories, share photos, spread your knowledge, and tell us how Scout can deliver great products and experiences. Along the way, Scout Motors will share our journey to production with you.

Scout is all about respect. We respect our heritage. We respect the land and outdoors. We respect each other. Every person should feel safe, included, and welcomed in the Scout Community. Being kind and courteous to the other forum members is non-negotiable. Friendly debates are welcomed and often produce great outcomes, but we don't want things to get too rowdy. Please take a moment to consider what you post, especially if you think it may insult others. We'll do our best to encourage friendly discourse and to keep the discussions flowing.

So, welcome to the Scout Community! We encourage you to check back regularly as we plan to engage our members, share teasers, and participate in discussions. The world needs Scouts™. Let's get going.

We are Scout Motors.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This completely.PLEASE dont do IFS or IRS on the scout. Solid Axles provide such better performance while offroading (for the most part) and are normally way more durable when compared to independent suspension systems

But do you attach the motor directly to the axle? You increase unsprung weight, but not having to worry about driveline/pinion angles could give a lot more flexibility in suspension design.

I prefer being locked front, rear and center, but I don't think that's practical. Maybe dual motor, one for front, one for rear, with each of those ends being locked. Let the computers handle speed-matching front-to-rear.

I prefer being locked front, rear and center, but I don't think that's practical. Maybe dual motor, one for front, one for rear, with each of those ends being locked. Let the computers handle speed-matching front-to-rear.

Question about EVs in general: when running multiple motors, can the RPM be controlled with identical output? Basically emulating a locker? Or when you lift a wheel off the ground, does that motor automatically spin faster due to no load on it? I'm thinking something akin to a stepper motor where the rotation is precisely controlled. If all wheels are turning at the same RPM, regardless of traction, I don't need an actual locker.

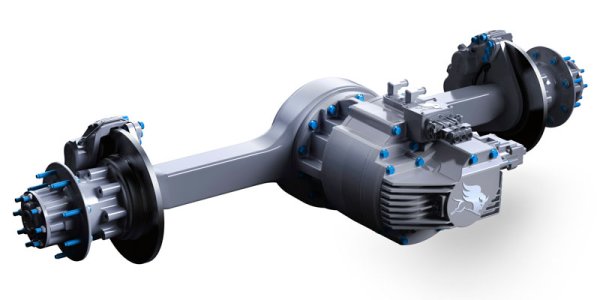

I'd seen these online somewhere, an e-axle I think? I like the concept... having an extra hundred lbs. of unsprung weight per axle might be an issue.View attachment 69A lot of companies are doing retrofits where the motor mounts straight to the pumpkin

I don't think so.I'd seen these online somewhere, an e-axle I think? I like the concept... having an extra hundred lbs. of unsprung weight per axle might be an issue.

I think these axles coupled with the Edison model of EV would be perfect. Sure more unsprung weight, but the weight would be low, keeping the Scout planted. It would inherently have lockers front and rear. It would be upgradable: Swapping motors for more powerful or efficient models. It would make lifting the vehicle simple and familiar.

Easy to switch between 2 and 4wd, one axle could be turned off to save power, and built-in traditional lockers... I like it. Saves space topside for batteries & provides a little ballast low down to even weight out. I like it a lot.

Like seriously... think about NOT having drivelines limiting articulation. We'd be limited by steering and suspension only. Gone would be the days of candy-caning drivelines.

I hope this has been seriously considered, if not already tested. It'd simplify a lot, and give gearheads something to tinker with... would there be any advantage to having a selectable geared low-range on a BEV?

Limiting wheel speed could be an advantage (could be done other ways) but I know that there are times I don’t necessarily need 4 low for traction but like it to limit speed in sketchy situationsI hope this has been seriously considered, if not already tested. It'd simplify a lot, and give gearheads something to tinker with... would there be any advantage to having a selectable geared low-range on a BEV?

What company is this from?View attachment 69A lot of companies are doing retrofits where the motor mounts straight to the pumpkin

I've found these in an article about e-axle retrofits... I'd love to see them in action in a 4x4.What company is this from?

Ayup, I saw that too. Specifically, your picture is of the Meritor system. Currently they only have large applications. No one has lockers that I see.I've found these in an article about e-axle retrofits... I'd love to see them in action in a 4x4.

But that's SUPER intriguing.

Though it wouldn’t be too hard to make a retrofit kit for a standard axle. Something that bolts onto the diff cover bolt holes then goes over the axle and holds a motor with the output shaft facing the u joint of the diffAyup, I saw that too. Specifically, your picture is of the Meritor system. Currently they only have large applications. No one has lockers that I see.

But that's SUPER intriguing.

Should be doable with switched reluctance motors.Question about EVs in general: when running multiple motors, can the RPM be controlled with identical output? Basically emulating a locker? Or when you lift a wheel off the ground, does that motor automatically spin faster due to no load on it? I'm thinking something akin to a stepper motor where the rotation is precisely controlled. If all wheels are turning at the same RPM, regardless of traction, I don't need an actual locker.

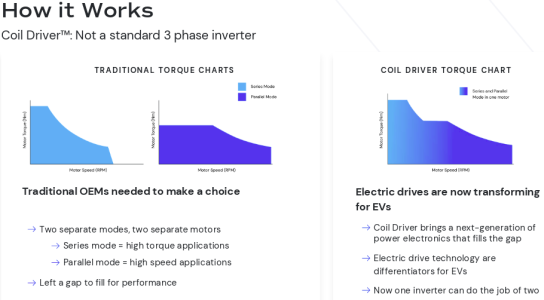

It can depending on motor type/design and application. Exro Technologies actually has a coil driver that can do just that electrically (without the weight, packaging, reliability, and efficiency penalty), possibly allowing more motors types to perform better in slow crawl scenarios without making other compromises. Maybe an alternative to using SRMs.I hope this has been seriously considered, if not already tested. It'd simplify a lot, and give gearheads something to tinker with... would there be any advantage to having a selectable geared low-range on a BEV?

Exro Technologies Presentation

A Dana 44 front & rear axle combined would weigh 298lbs and adding two 100lb motors to that would be near 500lbs, further more it seems GAWR wise one would need something closer to a Dana 60 of which the front axle alone weighs 305lbs.I'd seen these online somewhere, an e-axle I think? I like the concept... having an extra hundred lbs. of unsprung weight per axle might be an issue.

To put that in context, four in-wheel motors intended for a bus (elaphe M1100) would have a combined weight of 353lbs.

Last edited:

Could do a in-wheel motor setup similar to the Lordstown endurance's rear suspension (prototype pic below) but instead position the beam between the two in-wheel motors higher like a portal axle to increase ground clearance. That would definitely be unique.PLEASE dont do IFS or IRS on the scout. Solid Axles provide such better performance while offroading (for the most part) and are normally way more durable when compared to independent suspension systems

That said, with in-wheel motors imo an independent suspension system unencumbered by CV joints/shafts would be very formidable on or off road and the vehicle as a whole would be generally less compromised.

This makes me feel funny things in my no no squareCould do a in-wheel motor setup similar to the Lordstown endurance's rear suspension (prototype pic below) but instead position the beam between the two in-wheel motors higher like a portal axle to increase ground clearance. That would definitely be unique.

That said, with in-wheel motors imo an independent suspension system unencumbered by CV joints/shafts would be very formidable on or off road and the vehicle as a whole would be generally less compromised.

Which part? Just saying there are ways to meet people’s off-road performance expectations (personally think exceed) without resorting to what would for all intensive purposes be a Jeep Rubicon retrofit EV and all the sacrifices that come with that to range, weight, interior room, storage, turning radius, maintenance, ride quality, driving dynamics on or off road and likely purchase price.This makes me feel funny things in my no no square

Last edited:

Some like Rivian are doing "virtual" lockers using sensors and software to control multiple motors. Linked is a good (but long) review covering some light offroading in the Rivian R1T and R1S. The reviewer (Kyle Conner) pretty regularly says he would prefer a real locker.Question about EVs in general: when running multiple motors, can the RPM be controlled with identical output? Basically emulating a locker? Or when you lift a wheel off the ground, does that motor automatically spin faster due to no load on it? I'm thinking something akin to a stepper motor where the rotation is precisely controlled. If all wheels are turning at the same RPM, regardless of traction, I don't need an actual locker.

Rivian R1S vs R1T

Similar threads

- Replies

- 17

- Views

- 436

- Replies

- 11

- Views

- 348